You’ve probably struggled with a stubborn bolt or a stuck fastener before. Wasted minutes, lost patience, maybe even a few choice words. That’s exactly why

3 16 quick release pins

exist. They make connecting and disconnecting parts simple, fast, and reliable.

3 16 Quick release pins work by using a spring-loaded ball locking mechanism. When you pull or press the handle, the balls retract into the pin body, allowing insertion or removal. Release the handle, and the balls extend back outward, locking the pin in place

That’s the simple answer. But as with most engineering marvels, the devil’s in the details. Let me walk you through the full story.

Why Quick Release Pins Matter in Modern Manufacturing?

I often tell my clients — it’s not just about holding parts together. It’s about doing it quickly, safely, and repeatably.

Imagine assembling aircraft seats, race car panels, or industrial machinery. If every pin needed a wrench, your labor costs would skyrocket. Quick release pins save time, reduce errors, and increase productivity .

The Core Mechanism — Ball Locking System

The genius of the quick release pin lies in its ball locking system.

Here’s how it works:

The pin body has small holes near the tip.

Steel balls sit in those holes, partially protruding.

Inside the pin, a spring pushes the balls outward.

A button or handle at the top compresses the spring.

When compressed, the balls retract into the body, letting you slide the pin through a hole. Release it, and the spring forces the balls outward, locking the pin securely.

Simple? Yes. Reliable? Absolutely.

Types of Quick Release Pins

Not all quick release pins look the same. Customers often ask me: “Which one do I need?”

T-handle pins — Easy grip, good for frequent removal

Ring handle pins — Compact, convenient for tight spaces

Button head pins — Sleek, low-profile design

Custom designs — Whatever shape your engineers dream up

Each style uses the same ball lock principle, but the handle changes usability and ergonomics.

Materials That Make Them Reliable

At SKN Fastener, we don’t mess around with material quality.

Most of our pins are made from 304 stainless steel, offering corrosion resistance and strength. For marine or extreme environments, we recommend 316 stainless steel.

Handles might be stainless, aluminum, or reinforced plastic — it depends on application and cost sensitivity.

The material directly impacts load capacity, durability, and lifespan. Choose wrong, and you’ll regret it after the first rust patch.

Load Capacity and Safety

One of the first questions from buyers is: “How strong are these pins?”

Load ratings depend on:

Pin body diameter

Ball size and hardness

Spring strength

Material grade

We perform tensile and shear testing in-house to ensure every batch can withstand its rated loads. Because when safety is on the line, “close enough” isn’t good enough.

Surface Treatment and Corrosion Resistance

Even the strongest pin can fail if it corrodes. That’s why surface treatment matters.

Our common treatments include:

Passivation for stainless steel (removes impurities, improves corrosion resistance)

Zinc plating for budget-friendly protection

Black oxide for a matte, professional look

These treatments don’t just improve performance — they also make your product look premium, which is important if you’re reselling under your brand

Applications of Quick Release Pins

Where do you find quick release pins? Pretty much anywhere speed and reliability matter.

Aerospace — Seat tracks, access panels

Automotive — Race cars, clutches, body panels

Industrial equipment — Machine guards, adjustable fixtures

Marine — Deck fittings, rigging systems

Sports gear — Gym equipment, bicycles.

Every industry has one thing in common: wasted time is wasted money. Quick release pins prevent both.

Advantages Over Traditional Fasteners

Let’s be honest — a nut and bolt can do the same job, but at a cost.

With quick release pins you get:

Tool-free operation

Faster assembly/disassembly

onsistent locking force

Reduced wear on mating parts

Higher efficiency in production

This is why more and more B2B buyers are shifting toward quick release solutions.

How We Ensure Reliability at SKN Fastener

It’s one thing to understand how they work. It’s another to produce thousands consistently.

At SKN Fastener, our process includes:

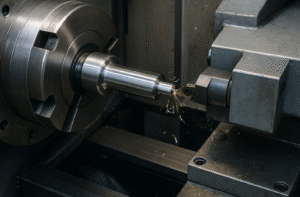

CNC turning and milling for precision pin bodies

Stamping and mold forming for ball seats

Spring and button assembly

Surface treatment for corrosion resistance

Testing with coordinate measuring machines and load rigs.

Every step ensures the mechanism works the same — first pin to last pin.

Related Questions We Hear Often

How are quick release pins made?

They’re made through CNC machining, precision assembly of ball/spring mechanisms, surface finishing, and quality testing.

Can quick release pins be customized?

Yes. We offer custom diameters, lengths, handles, and finishes

Do they rust?

Not if you choose the right material and finish for your environment. Stainless steel with passivation resists corrosion for years.

More Related Questions

Are quick release watch pins as strong as industrial ones?

No — watch pins are designed for light loads, not heavy machinery.

Do you ship globally?

Yes. Our main markets are the US, Canada, and Europe .

Can I order small batches?

We’re wholesale only, but MOQ is flexible depending on customization.

Conclusion

Quick release pins work through a simple yet brilliant mechanism — retracting balls and a spring-driven lock. But behind that simplicity is precision engineering and strict quality control. That’s how we ensure our pins don’t just work once — they work every time.