Quick release pins are widely used in automotive, aerospace, construction, and machinery industries for fast, secure, and tool-free assembly. They improve efficiency in equipment maintenance, structural connections, and modular systems. From medical devices to marine engineering and renewable energy setups, these pins offer reliable performance and easy operation across demanding environments.

Custom Fastener Wholesale

You Need More Than a Supplier—You Need a Fasteners Partner

Whether you’re a heavy equipment OEM reinforcing structural integrity or an aerospace maintenance provider demanding zero-failure components, our precision fasteners deliver three non-negotiable advantages: cross-industry adaptability, extreme environment survivability, and smart load intelligence.

From quick release pins securing offshore wind turbine access points to vibration-proof bolts maintaining high-speed rail track stability, we transform standard fastening into strategic asset protection.

Trusted by Global Leaders

▌ Core Hydraulic Coupling Supplier for Sany Heavy Industry

▌ Exclusive Anti-Loosen Bolt Partner for CRRC Group High-Speed Rail

▌ Strategically Certified for Vestas Wind Tower Connection Systems

Our Advantage

Precision-forged from aerospace-grade alloys and combat-proven polymers, our fasteners deliver uncompromising reliability where failure isn’t an option. Trusted by high-speed rail engineers and wind farm operators to secure critical connections from -40°C tundras to desert combat zones. When your application demands fastener IQ, not just hardware – we’re locked and loaded.

Why Choose US

Hot Selling Products

We pride ourselves on offering a wide range of top-quality Fastener products that are in high demand. Whether you’re looking for quick release pin Or Customize for which types staff, or customizable promotional items, our fastener products are designed to meet the needs of businesses like yours.

General Application for Fasteners

construction

automotive

aerospace

Wind power field

Medical

Line array

Rail transit

Fitness Equipment

Costs Breakdown

The final cost of your order depends on factors like raw material customization, quantities, and shipping. Below is a breakdown of key cost elements:

Customization and Design

Custom features like logos, colors, or unique shapes require specialized molds and adjustments, impacting the cost.

Raw Material Selection

Different material effect the price. We calculate price according to different material, like 17-4, stainless steel 304, 316, price is different.

Production Quantities

For 1pcs and 1000pcs, price is different. As we purchase raw material according to order. If we purchase bulk big order raw material, the raw material is cheaper than small order.

Shipping and Logistics

Shipping costs vary based on order size, quantities, distance, and transport method (air, sea, or land).

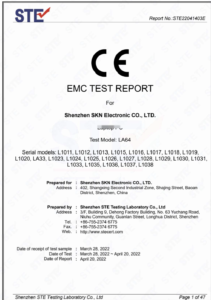

Compliance and Certifications

Certain products require certifications (e.g., CE, Rohs FCC), which can add to the overall cost but ensure safety and regulatory compliance.

Packaging and Handling

Custom or bulk packaging, as well as the handling of delicate products, can impact the total cost. Example, if customize customer own brand packages, that will cost more. We can support you different kind of material packages.

Manufacturing Process & Estimation

The final timeline for manufacturing depends on the level of customization, materials, and production volumes. Below is a general breakdown of the process flow and estimated durations for our fasteners products:

Step 1: Initial Consultation (1 days)

During this step, we gather all the necessary details about your project, including product specifications, customization options, and any regulatory requirements. This ensures that we understand your needs fully before moving forward.

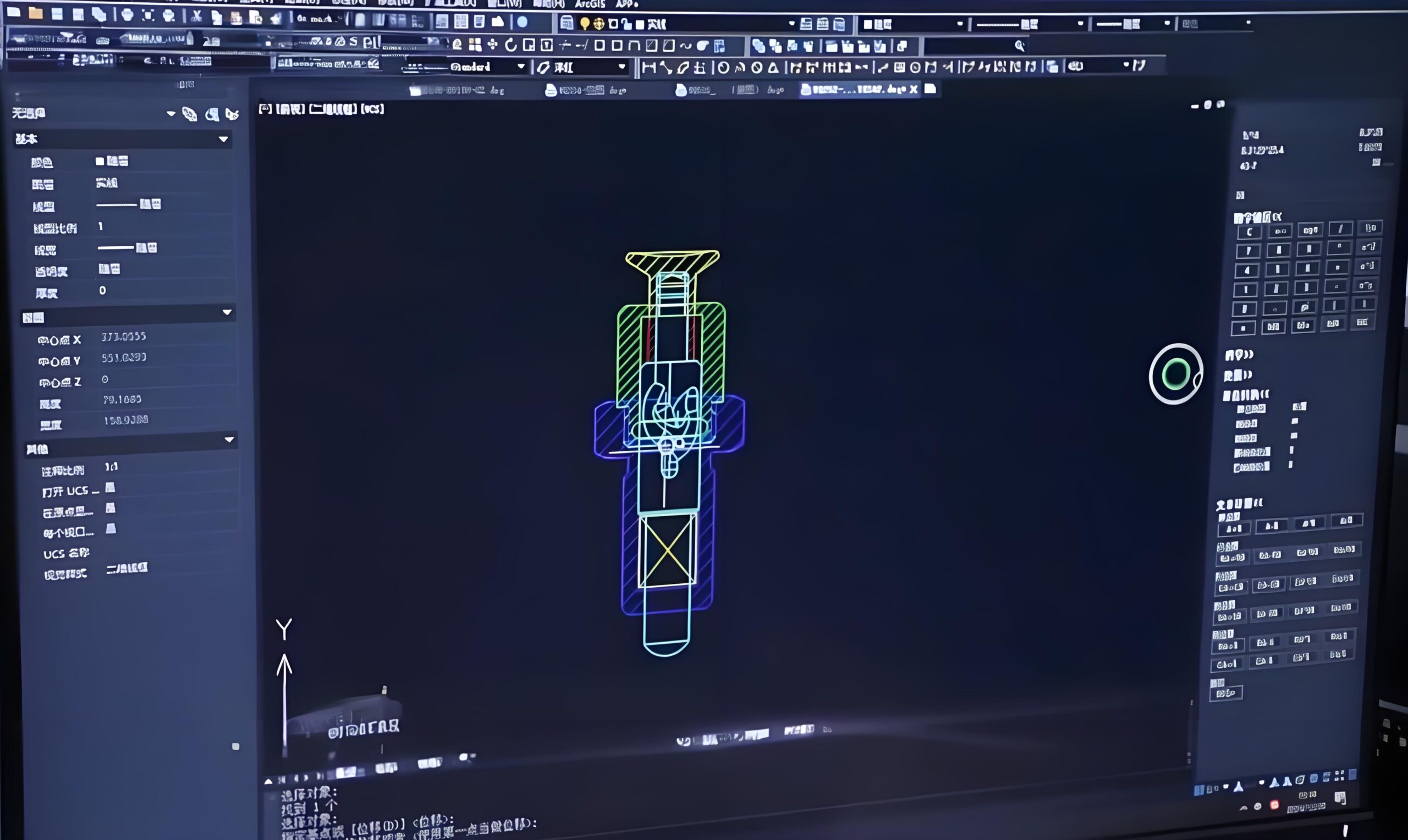

Step 2: Design & Prototype (1-7 days)

Once we have all the details, our design team works on creating a prototype based on your specifications. This stage includes any logo placements, custom colors, and shape modifications. You will receive a prototype to approve before proceeding to production.

Step 3: Order Confirmation (1-2 days)

After approving the prototype, we will finalize the order details, including quantity, pricing, and shipping preferences. Once everything is confirmed, we proceed to the next step.

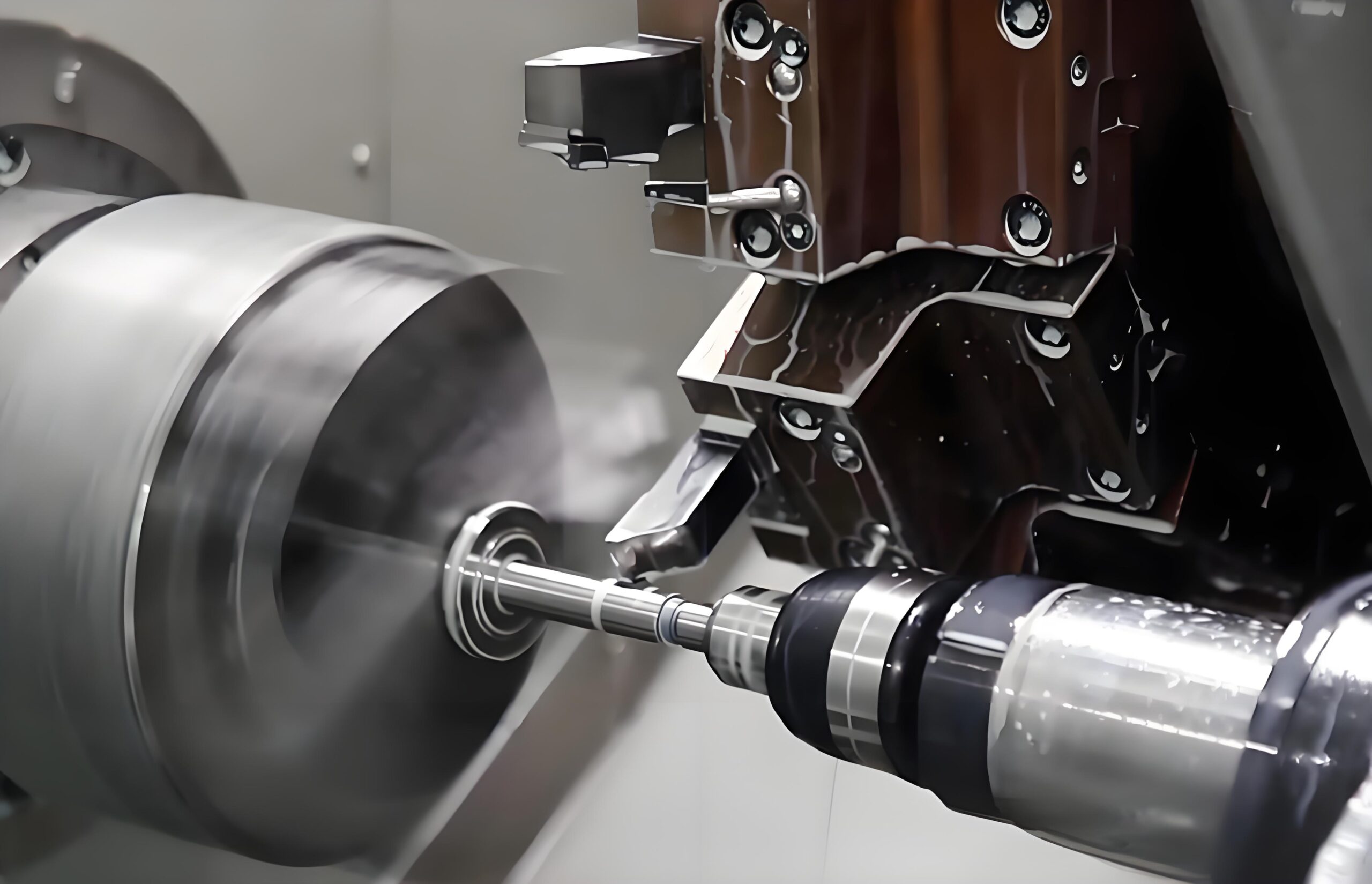

Step 4: Bulk Manufacturing (10-15 days)

With the order confirmed, our team starts the manufacturing process. During this stage, we produce the bulk quantity of your fasteners products, ensuring strict quality control throughout.understand your needs fully before moving forward.

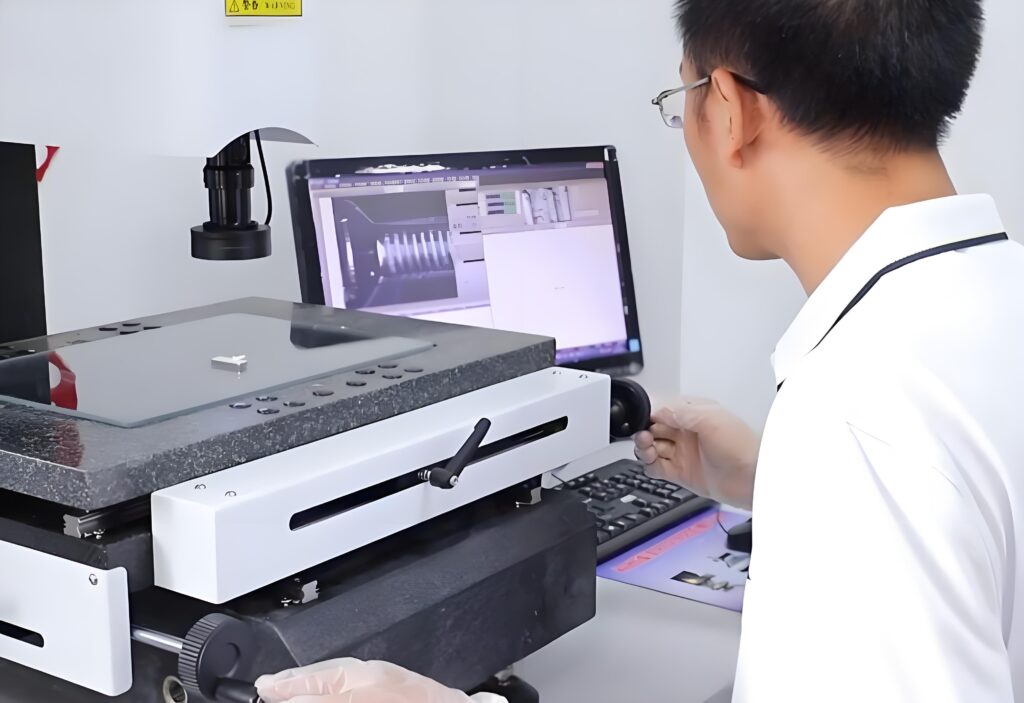

Step 5: Quality Inspection & Packaging (1-2 days)

Once the products are manufactured, we conduct a thorough quality check to ensure they meet your requirements. After inspection, the products are packaged and prepared for shipping.

Step 6: Shipping & Delivery (4-15 days)

Finally, the products are shipped to your specified location. Delivery time varies based on the destination and chosen shipping method (air, sea, or land).

Want to know how to compress lead times?

If you need faster delivery, we offer options to streamline the process and reduce lead times. Contact us for more details.

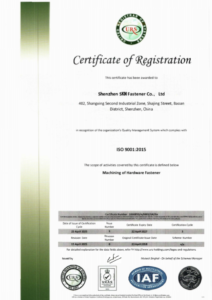

Certification

We uphold the highest standards of quality and safety. Our fasteners products are certified to meet CE, and ISO 9001 requirements, ensuring compliance with global regulations.

Brands Trust Us

A Bridf Self-Nomination, Why Choose SKN

At SKN Electronic, we are committed to delivering high quality fastener products that meet your exact needs.

With over a decade of experience, we ensure that every product we manufacture upholds the highest standards of durability, safety, and customization.

Here’s why our clients choose us:

- 30,000+ Successful Projects – We’ve supported over 30,000 businesses globally with fasteners that elevate their products.

- 10,000 Units per Day – Our high-capacity production facility enables us to meet even the largest orders with efficiency and precision.

- Over 500 Customization Options – From colors and sizes, we offer unmatched flexibility to fit your brand’s vision.

- Strict Quality Control – We inspect every product at multiple stages, ensuring zero defects in each batch.

- Precise Materials – We use only A glasss material, global sustainability standards.

Partnering with us means working with a trusted manufacturer dedicated to providing solutions that align with your brand’s needs.

The FAQ's Throughout The Trading Process

To help you make an informed decision about partnering with SKN fasteners, we’ve answered some of the most frequently asked questions below. Whether you’re new to fasteners products or already a pro, these answers will guide you through the process.

We specialize in a wide range of fasteners products, including quick release pin, ball lock pin, nuts, index plunger, ball rollers, ball plunger, dowel pin , and more. All our products are made from high-quality, multifunction to meet your specific requirements.

Absolutely! We offer flexible customization options, including color, shape, size, and logo branding. Whether you need a completely unique design or simple adjustments, we’re happy to help bring your vision to life.

Our MOQ varies depending on the product type and customization requirements. Generally, we work with larger orders due to our manufacturing capabilities, but we can accommodate smaller orders if necessary. Please reach out to us for specifics.

If you buy our inventory products, it will be 1-2days. If customize, Production times typically range from 10 to 15 days, depending on the complexity of the customization and order volume. We also offer expedited services for urgent orders.

Military-grade 17-4PH stainless steel cores with German spring-lock mechanisms conquer extreme conditions (-50°C to 200°C) and 2000h salt spray tests. CNC-machined to ±0.03mm precision under IATF-certified processes, our pins deliver 0.1% defect rates—backed by 5-year warranties and lifecycle traceability. Proven in Caterpillar mining rigs and SpaceX rocket systems, they outperform industry durability standards by 300%.

We ensure quality from the source by selecting only certified raw materials and applying strict dimensional tolerance controls. Every quick release pin goes through a multi-step inspection process, including hardness testing, salt spray corrosion resistance, and 100% visual checks. Our production follows ISO 9001 standards, with full traceability from batch to shipment. We use precision CNC machining and automated assembly to minimize human error and ensure consistency. Final products are tested in real-world applications for durability, safety, and performance before delivery.

We offer various shipping methods, including air, sea, and land transport, depending on your location and order size. Shipping costs are calculated based on the volume, weight, and destination of your order. We aim to offer competitive rates and timely delivery.

Yes, we offer samples for you to test the quality and customization before committing to a bulk order. Please contact us to request a sample, and we’ll guide you through the process.

To get a quote, simply reach out to us with the product details, order volume, and customization requirements. We’ll provide a detailed quote with pricing and lead times.