Push button quick release pin

Push button quick release pin featuring an ergonomic contoured handle and push-button design. Built from stainless steel for durability and corrosion resistance, ideal for aerospace, fixtures, molds, and high-frequency tool changes.

This Push button quick release pin is designed for heavy-duty fastening where speed, safety, and precision are essential. The pin features a contoured handle for a comfortable grip, allowing operators to insert and remove the pin efficiently—even with gloves.

Built from high-grade stainless steel, the shaft and handle provide excellent resistance to corrosion and wear, making this pin ideal for indoor and outdoor industrial environments. The spring-loaded dual ball locking mechanism securely engages with the mating hole, preventing accidental withdrawal during operation.

Its sleek body profile and precise tolerances ensure smooth fit and repeatable performance in aerospace fixtures, robotic arms, modular tooling systems, and more.

✅ Technical Specifications

Material: Stainless Steel 304 / 316 (customizable)

Ball Material: SUS440C, HRC55+ hardened

Locking Mechanism: Spring-loaded dual ball system

Handle Type: Ergonomic contoured grip, integrated push-button release

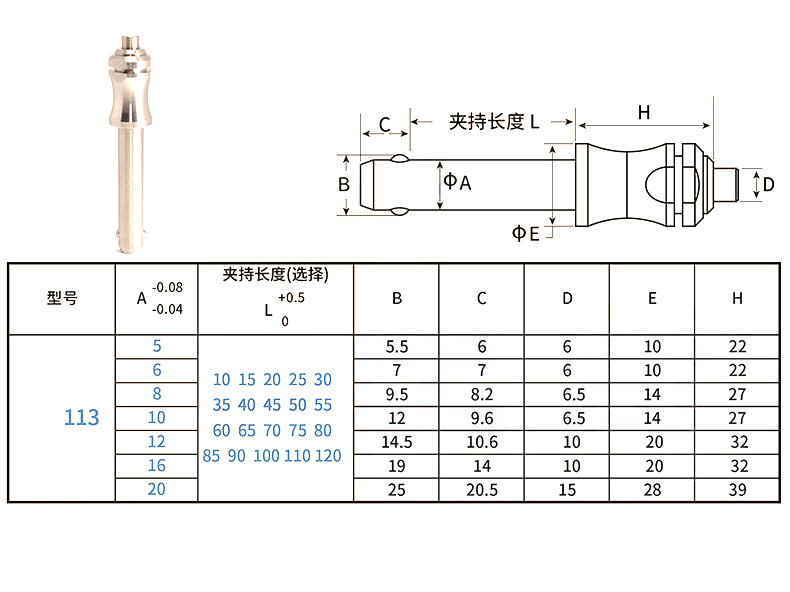

Diameter Range: Ø5 mm to Ø20 mm

Grip Lengths: 10 mm – 100 mm (custom available)

Surface Finish: Natural / Passivated / Brushed

Tolerance: ±0.05 mm

Cycle Life: Over 10,000 cycles

✅ Applications

Aerospace positioning fixtures

High-speed mold and die change systems

Modular tool change setups

Automotive assembly tooling

Precision mechanical assemblies

Robotics & automation arms

✅ Key Features & Benefits

Push-button release for fast and tool-free operation

Secure dual ball locking prevents accidental release

️ Precision fit with tight tolerances

Ergonomic contoured handle for better grip and control

Corrosion-resistant stainless steel construction

Custom sizes, logo engraving, and material upgrades available

✅ Ordering Guidelines

To receive a quote, please include:

Pin diameter and grip length

Preferred material (e.g., SS304 or SS316)

Quantity and delivery timeline

Special requests (e.g., coating, handle engraving, packaging)

Free Sample

VIP Service

Shipping order track

Free Return

Intact Guarantee

Why Choose SKN as Fastener Manufacturer

10+ Years Experience

With over a decade of experience in the fastener product industry, SKN has developed a deep understanding of diverse market demands and wholesale customer requirements.

- Operating 8 advanced production lines

- we manufacture up to 50,000 high-quality fastener products daily.

- Our commitment to excellence has enabled us to export to more than 30 countries worldwide, including the United States, Germany, Japan, and Australia, ect.

Strict Quality Control

Hardened and highly abrasion-resistant stainless steel raw materials and strict production quality control ensure that every product is high precision and high quality

- 100% high quliaty raw material

- Full quality inspection

- ISO 9001 standard

Strict Quality Control

Hardened and highly abrasion-resistant stainless steel raw materials and strict production quality control ensure that every product is high precision and high quality

- 100% high quliaty raw material

- Full quality inspection

- ISO 9001 standard