Struggling to find the exact quick release pin for your project? Choosing the wrong one means delays and poor fit. I'll guide you through a simple process to get it right.

To choose the right quick release pin, you must measure the pin's diameter1 and its grip length2. For new applications, measure your hole's diameter and the material's thickness. Then, select a handle type and material. This ensures a secure and functional fit for your specific needs.

Getting the measurements right seems complicated, but it is much easier than you think. I have helped countless clients with this exact problem. Over the years, I've learned that a few simple steps can prevent almost every common mistake. Let's break down the process together. This will help you order with confidence and avoid costly errors.

How do I measure the diameter and grip length2 correctly?

Are you confused by terms like "grip length2" and "overall length3"? A wrong measurement can make your new pins useless, which wastes both time and money. Let's clarify these key dimensions.

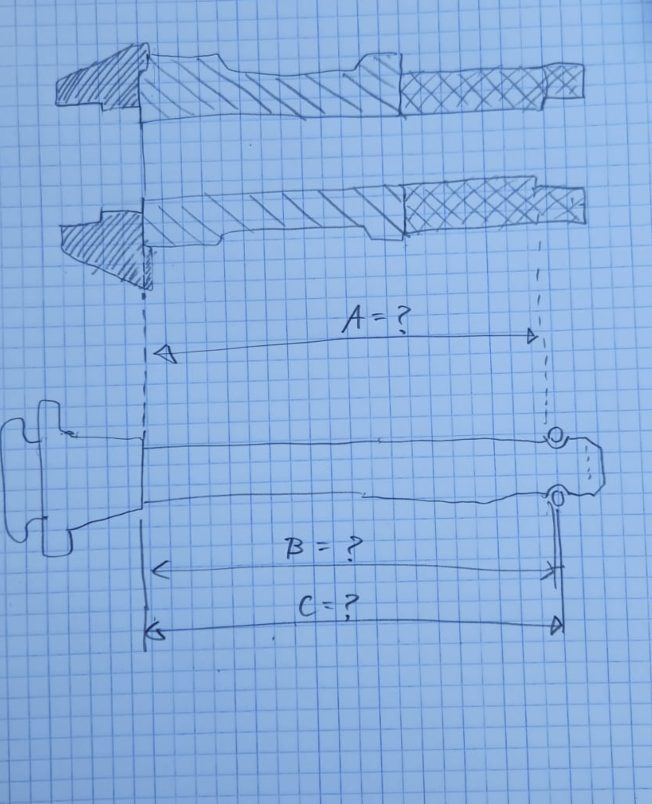

Use calipers4 to measure the pin's main shaft for the diameter. For grip length2, measure from just under the handle to the start of the locking balls5. This is the effective length that secures your parts together. Do not confuse it with the overall length3 of the pin.

When a new customer asks me for a quick release pin6, the first thing we talk about is measurement. Two dimensions are more important than all the others: diameter and grip length2. Understanding them is the key to a perfect fit.

Understanding Pin Diameter

The diameter is the thickness of the pin's shaft. It needs to match the hole in your application. If the pin is too small for the hole, the connection will be loose and wobbly, which can be unsafe. If the pin is too large, it simply will not fit. For the most accurate reading, I always recommend using a pair of digital calipers4. Measure the smooth, solid part of the pin shaft, not the end with the locking balls5. This single measurement ensures the pin will slide smoothly into your equipment.

The Importance of Grip Length

Grip length is the most critical measurement, and it is where most mistakes happen. It is the effective, usable length of the pin. You measure it from the bottom of the handle to the point where the locking balls5 begin to emerge. This length must match the total thickness of the materials you are fastening together. I remember a customer who ordered 500 pins based on the overall length3. When they arrived, the locking balls5 couldn't clear the material, so none of them would lock. It was a simple mistake, but it caused a big delay. We had to rush a new order with the correct grip length2.

Here is a simple table to help:

| Your Material Thickness | Recommended Grip Length | Why it Works |

|---|---|---|

| 20mm | 20mm (or 21mm) | This ensures the locking balls5 fully clear the material. |

| 45mm | 45mm (or 46mm) | A pin that is too short won't lock. |

| 100mm | 100mm (or 101mm) | A pin that is too long can be a snag or safety hazard7. |

What if I'm designing a new application without a previous pin?

Starting a new project and feeling unsure which pin specifications you need? Guessing the size can lead to design flaws and expensive rework later on. Here is how to determine the perfect pin size from your design.

For a new application, first measure the diameter of the hole. Next, measure the total thickness of the parts you need to fasten together. This thickness is your required grip length2. These two measurements are the foundation for selecting the correct quick release pin6 for your design.

Sometimes, a customer doesn't have an old pin to use as a reference. This is common for new products or custom machinery. In this case, we just measure the application itself. The process is very straightforward. It all comes down to the hole you have and the thickness you need to secure.

Measuring Your Application's Hole Diameter

First, you need to know the size of the hole. You can use digital calipers4 or a pin gauge8 to get an accurate inside measurement. The hole should always be slightly larger than the pin's nominal diameter. This small amount of clearance allows the pin to slide in and out easily. For example, if you want to use a 10mm diameter pin, a hole size of 10.1mm to 10.2mm is often perfect. If the hole is too tight, the pin might get stuck. If it's too loose, the connection will not be secure. I recently helped a client who was designing a new piece of gym equipment. They sent me their CAD drawings, and we saw the hole was specified at exactly 6mm for a 6mm pin. I recommended they increase the hole size to 6.1mm in their design to ensure smooth operation.

Determining the Required Grip Length

This step is even simpler. The required grip length2 is just the combined thickness of all the parts you are pinning together. Imagine you are fastening two metal plates. If Plate A is 15mm thick and Plate B is 20mm thick, your total material thickness9 is 35mm. Therefore, you need a pin with a grip length2 of 35mm. It is always better to have a grip length2 that is slightly too long than one that is too short. A pin that is too short will fail to lock, making it completely useless. A pin that is a few millimeters too long will still function perfectly.

Which handle type and material should I choose?

Are you overwhelmed by the different handle styles and material options for your pin? The wrong choice can affect usability, durability, and even safety in your application. Let's break down the common options to simplify your decision.

Choose a handle based on your usage needs. T-handle10s offer a firm grip, while L-handle11s are compact. For material, stainless steel12 is great for corrosion resistance, while alloy steel13 offers higher strength. Your application's environment and load requirements will determine the best choice.

After we figure out the dimensions, the next conversation is always about the handle and the material. These choices depend entirely on how and where the pin will be used. A pin used outdoors on a boat has very different needs than one used on an indoor factory assembly line.

Selecting the Right Handle

The handle choice is mostly about user convenience and space. When I talk to a new client, I usually show them pictures of the main handle types. This helps them visualize how they will use the pin.

| Handle Type | Best For | Considerations |

|---|---|---|

| T-Handle | Frequent use, applications requiring a firm grip | Can be bulky and may interfere with nearby parts. |

| L-Handle | Tight spaces where a T-handle10 will not fit. | Offers less leverage than a T-handle10. |

| Button Handle | Flush-mount applications to prevent snags. | Can be harder to pull out, especially with gloves. |

| Ring Handle | Attaching lanyards, easy pulling from any angle. | The ring can sometimes get caught on other equipment. |

Choosing the Pin Material

The final step is choosing the material. This choice is all about balancing strength, cost, and resistance to the environment. I always ask, "Will this pin be used indoors or outdoors? Will it get wet?" The answer tells me exactly what to recommend. For most procurement managers, the key is finding a reliable material that meets performance requirements without being too expensive. Stainless Steel, like 304 or 316, is perfect for outdoor, marine, or food-grade applications because it resists rust very well. Alloy Steel, on the other hand, is much stronger and more durable. It is ideal for high-load or heavy-wear situations but needs a protective coating like zinc plating to prevent corrosion.

What if I'm still not sure about the size?

Still feeling uncertain about your measurements even after following all the steps? Ordering a large batch with the wrong specifications is a costly and frustrating mistake. There's a risk-free way to confirm your choice.

If you are ever unsure, the best solution is to request a sample. Provide us with your best-guess measurements, and we can produce a single prototype pin. You can then test this sample in your actual application to confirm the fit and function before placing a large order.

Even with careful measurements, there can still be some doubt. This is especially true for complex assemblies or high-volume orders where a mistake would be very expensive. For any customer who is not 100% confident, my advice is always the same: let's make a sample first.

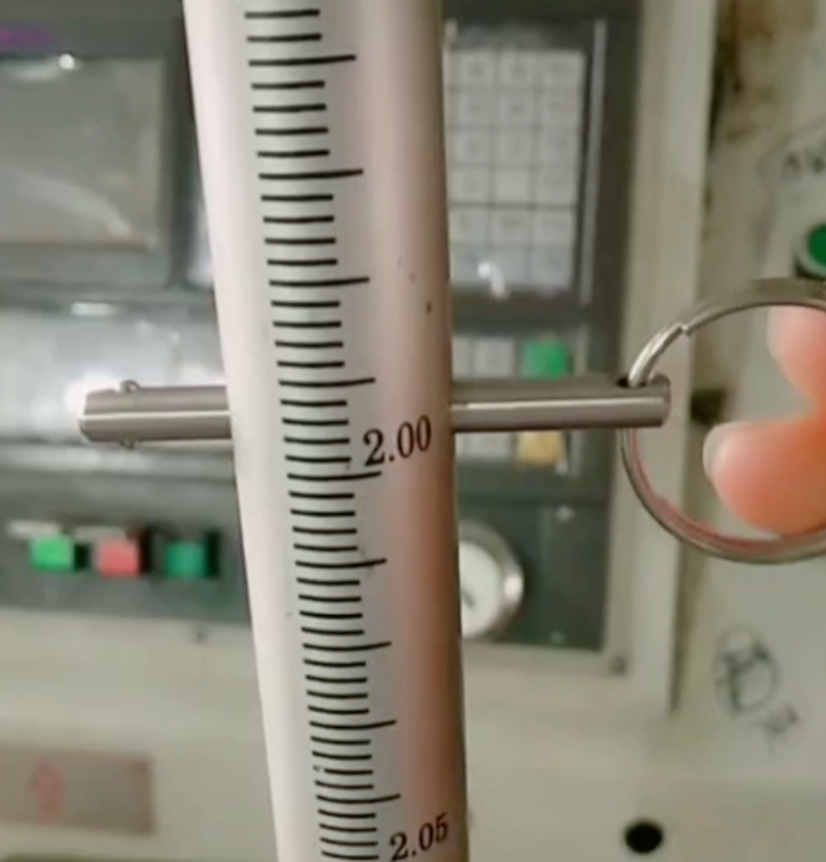

The Power of a Prototype

A physical sample removes all guesswork. It is a small investment that prevents a big problem. I worked with a procurement manager for a large OEM who was sourcing 5,000 pins for a new assembly line. The drawings were complex, and he was worried about the grip length2. I told him, "Let's not guess. Give me the dimensions from the drawing, and I will send you one pin to test." We made the sample and sent it to him. It turned out the pin needed to be 2mm longer than the drawing specified to work smoothly. He was so relieved. That one sample saved his project weeks of delay and thousands of dollars. It gives buyers, especially those managing large projects, complete confidence and reduces supply chain risk.

Our Prototyping Process

The process is simple and designed to give you peace of mind.

- Provide Specs: You give us your best-guess dimensions (diameter, grip length2), handle type, and material choice.

- We Manufacture: We produce a single, fully functional quick release pin6 based on your specifications.

- You Test: We ship the sample directly to you. You can then test it in your actual equipment to check the fit, function, and feel.

- Confirm or Adjust: You either confirm that the sample is perfect, or you tell us what needs to change.

- Full Production: Once you approve the sample, we proceed with the bulk production order, knowing it's exactly what you need.

Conclusion

Choosing the right quick release pin6 is easy when you measure correctly. Focus on diameter and grip length2, select the right handle and material, and always test a sample first.

Learn the best techniques for measuring a pin's diameter to ensure a perfect fit in your application. ↩

Discover the importance of grip length and how it affects the performance of quick release pins. ↩

Clarify the distinction between overall length and grip length to avoid common measurement mistakes. ↩

Find out which calipers provide the most accurate measurements for your quick release pin projects. ↩

Understand the role of locking balls in ensuring the security and functionality of quick release pins. ↩

Explore this resource to understand the functionality and applications of quick release pins in various projects. ↩

Understand the potential safety risks of using incorrectly sized quick release pins. ↩

Explore the use of pin gauges for accurate measurements in quick release pin applications. ↩

Get tips on accurately measuring material thickness to select the right quick release pin. ↩

Explore the benefits of T-handles for quick release pins and when to use them. ↩

Learn about L-handles and their suitability for tight spaces in your projects. ↩

Discover the advantages of using stainless steel for quick release pins in various environments. ↩

Understand why alloy steel is a strong choice for high-load applications involving quick release pins. ↩