Как изготавливаются быстросъемные штифты?

Ever tried pulling a quick release hitch pin and felt it fight back? Or worse — it’s too loose, and you wonder if it’ll pop out mid-operation. That’s the danger of poor manufacturing. Bad pins cost you time, money, and customer trust.

Good quick release hitch pin don’t happen by accident. They’re the result of precise engineering, smart material choices, and rigorous testing — the kind we live by at SKN Fastener.

If you’ve ever wondered what happens between raw metal and the perfectly smooth pin in your hand, let me take you behind the scenes.

Why I Care About Manufacturing Quality

When I started SKN Fastener in 2012, I noticed too many suppliers treated quick release pins like “just another small part.” That’s a recipe for disaster.

A quick release pin is often the only thing standing between a stable assembly and a safety hazard. If that pin fails, so does the product — and your reputation.

Step 1: Selecting the Right Material

Before any machine starts humming, we choose the raw material.

For most applications, 304 stainless steel is our go-to. It offers the perfect balance of corrosion resistance, strength, and cost-effectiveness . Some applications demand galvanizing or alternative grades — we’ll match the material to the environment and load requirements.

The wrong material means premature wear, rust, or even mechanical failure. We don’t take that gamble.

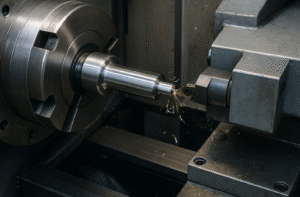

Step 2: Pin Body Manufacturing

Here’s where things get technical.

The pin body is made through high-precision turning or milling processes. Our CNC lathes shape the steel so that the diameter и clamping length meet exact tolerances.

Why the fuss over a fraction of a millimeter? Because the fit determines how securely the pin locks and how easily it releases. Too big, and it won’t insert; too small, and it rattles or wears out the mating hole.

Step 3: Creating the Ball Locking Structure

This is the “magic” part most users never see.

The locking mechanism uses стальные шары housed inside the pin. When you press the button or pull the handle, the balls retract. Release it, and they pop out, locking the pin in place.

We form this mechanism through precision mold forming or stamping. It’s delicate work — the ball seat must be perfectly shaped to ensure smooth movement without excess play .

A sloppy mold here means a pin that sticks, wears out quickly, or fails under load.

Step 4: Assembly of Spring and Button

A ball lock is useless without the spring and button to control it.

We insert a precision spring that pushes the balls outward, and a button or handle that compresses the spring when actuated. This step demands accuracy — spring tension determines how easy or hard it is to operate the pin.

Too much tension, and your end user needs superhero strength. Too little, and the pin can release unintentionally.

Step 5: Surface Treatment for Durability

Even the best steel benefits from protection.

Depending on the order, we either:

Polish and passivate stainless steel for a smooth, shiny finish

Galvanize for added corrosion resistance

Apply black oxide for a matte, low-reflection look

This isn’t just cosmetic. A good surface finish prevents rust, extends lifespan, and improves handling comfort.

Step 6: Quality Control and Dimensional Testing

This is where I lose patience with cut-rate suppliers. They’ll produce thousands of pins and “eyeball” them. That’s asking for trouble.

We run every batch through precision testing equipment like a coordinate measuring machine (CMM) to confirm dimensional accuracy. We check:

Pin diameter and length

Ball engagement depth

Spring force

Surface finish quality

If a pin fails, it’s scrapped — not shipped.

Step 7: Final Packaging and Logistics

A perfectly made pin still needs to arrive perfectly.

We package bulk orders in moisture-resistant materials and label them for easy identification. For our B2B clients in the US, Canada, and Europe, we coordinate shipping to align with their peak sales seasons .

Late deliveries? Not on my watch.

Typical Processing Equipment in Our Workshop

When customers visit our 10,000 m² facility, they’re often surprised by the variety of machines involved:

Lathe — For turning and milling pin bodies

Press — For forming the ball lock mechanism

Injection molding machines — For plastic or composite handles

Coordinate measuring machine (CMM) — For ultra-precise dimensional checks

This mix of traditional and high-tech equipment gives us both volume capacity and custom flexibility.

How This Process Solves Real-World Problems

Remember John , my importer friend in the US? His old supplier split production between two factories — one made the bodies, another assembled them. Result? Misfits, delays, and endless back-and-forth emails.

We keep every step in-house, from cutting the first rod to boxing the final shipment. That means fewer delays, tighter quality control, and no finger-pointing between subcontractors.